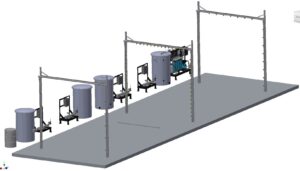

Designed to remove free hydrocarbons and filter water, these systems come standard with pH and ORP injection and are corrosion-resistant when utilizing polymer tanks and recycled plastic skids.

Features:

·Cone-shaped tank

·Heavy-duty corrosive-resistant base

·Clarifier water/oil/solids separator

·Corona discharge ozone system

·Oil decanter

·Sludge box

·Multi-media, reusable polyester and activated carbon filters

·ORP/pH controller

·1.0 HP surface-mount sump pump

·ETL listed NEMA-4 rated corrosion-proof control panel

Accessories:

·Replacement multi-media

·Replacement carbon

·Check valve

Options:

·Automatic dump valve (Standard on auto-backwash models)

·460V, 3Ø

·Coagulation system

·Auto-backwash (Cartridge filter not available)

Consult Mi-T-M Equipment Sales & Service for more information.